The Role of Thermal Imaging in Off-Gassing Monitoring – Oil and Gas

The extraction, processing, and transportation of oil and gas involve various operational aspects that come with inherent risks, one of them being off-gassing. Off-gassing refers to the release of volatile compounds or gases during industrial processes, which can pose safety hazards to workers, impact the environment, and lead to potential financial losses for companies. In this context, the application of thermal imaging technology has emerged as a valuable tool for monitoring and managing off-gassing activities in the oil and gas industry. This blog explores the significance of thermal imaging in detecting and addressing off-gassing issues, highlighting its benefits, applications, and best practices for maximizing safety and efficiency in oil and gas operations.

Significance of Thermal Imaging in Off-Gassing Monitoring:

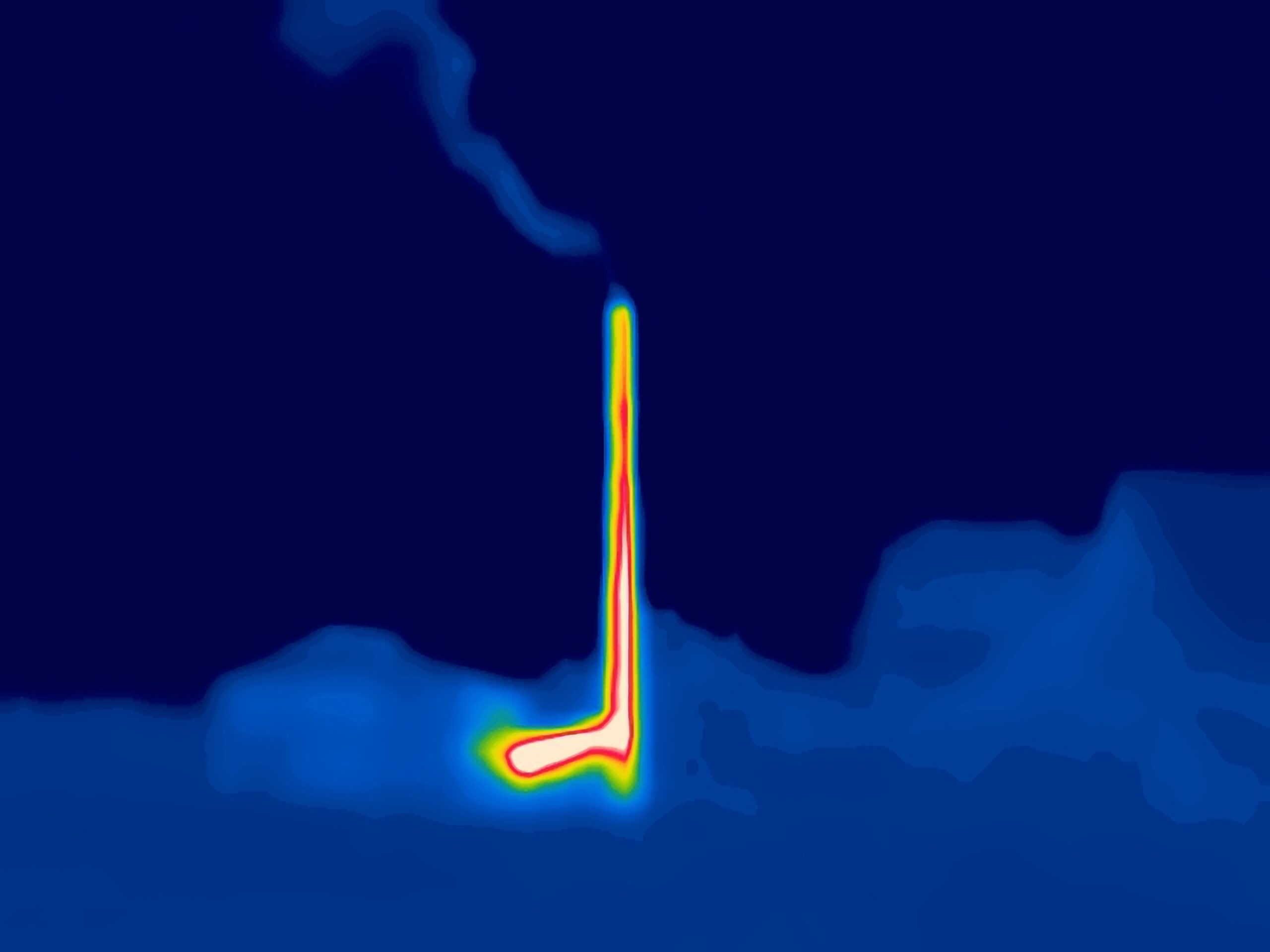

Off-gassing events in the oil and gas industry can result from various activities such as drilling, refining, storage, and transportation of petroleum products. These processes can release volatile organic compounds (VOCs), hydrocarbons, sulfur compounds, and other hazardous gases into the atmosphere, posing risks to workers and the environment. Traditional methods of detecting off-gassing, such as manual inspection or gas detection sensors, have limitations in terms of coverage, accuracy, and real-time monitoring capabilities. Thermal imaging technology offers a non-intrusive, remote-sensing solution that enables continuous monitoring of off-gassing emissions by detecting changes in temperature and thermal patterns associated with gas releases.

Benefits of Thermal Imaging for Off-Gassing Detection:

Thermal imaging cameras are designed to capture infrared radiation emitted by objects based on their temperature, allowing users to visualize thermal gradients and anomalies in the surrounding environment. When applied to off-gassing monitoring in the oil and gas industry, thermal imaging offers several benefits:

1. Early Detection: Thermal imaging can detect off-gassing events at an early stage, providing operators with timely alerts to mitigate potential risks before they escalate.

2. Remote Monitoring: Thermal cameras can be deployed in hard-to-reach or hazardous areas, enabling remote monitoring of off-gassing activities without direct human intervention.

3. Enhanced Safety: By identifying gas leaks or emissions promptly, thermal imaging helps improve workplace safety by minimizing exposure risks for personnel and preventing accidents.

4. Data Logging and Analysis: Thermal imaging systems can record and analyze thermal data over time, allowing operators to track off-gassing trends, conduct post-incident investigations, and optimize preventive maintenance strategies.

5. Compliance Assurance: By implementing thermal imaging for off-gassing monitoring, oil and gas companies can demonstrate regulatory compliance with environmental standards and emission limits.

Applications of Thermal Imaging for Off-Gassing Management:

The versatility of thermal imaging technology makes it suitable for a wide range of off-gassing monitoring applications within the oil and gas industry:

1. Leak Detection: Thermal cameras can identify gas leaks from pipelines, valves, storage tanks, and equipment by visualizing temperature differentials associated with escaping gases.

2. Emission Screening: Thermal imaging enables screening large areas or facilities for off-gassing emissions, allowing operators to pinpoint sources and quantify gas releases.

3. Inspection of Flare Systems: Thermal imaging can assess the performance of flare systems by monitoring flame temperatures, combustion efficiency, and smokeless operation to minimize off-gassing events.

4. Emergency Response: In the event of an off-gassing incident or emergency, thermal imaging can aid emergency responders in assessing the extent of the release, implementing containment measures, and ensuring worker safety during response operations.

Best Practices for Off-Gassing Monitoring with Thermal Imaging:

To optimize the use of thermal imaging for off-gassing management in the oil and gas industry, companies should consider the following best practices:

1. Regular System Calibration: Ensure that thermal imaging cameras are calibrated and maintained according to manufacturer specifications to maintain accuracy and reliability in off-gassing detection.

2. Integration with Monitoring Systems: Integrate thermal imaging data with existing monitoring systems, alarm systems, and data analytics platforms to streamline off-gassing monitoring and response processes.

3. Staff Training and Awareness: Provide training to personnel on the operation, interpretation, and safety considerations

Conclusion:

In conclusion, the utilization of thermal imaging technology for monitoring off-gassing in the oil and gas industry presents a valuable opportunity to enhance safety protocols, increase operational efficiency, and mitigate environmental impacts. By leveraging the capabilities of thermal imaging cameras to detect and visualize gas leaks or emissions in real time, operators can proactively address potential hazards, minimize downtime, and promote a safer working environment for personnel. As advancements in thermal imaging continue to evolve, incorporating these innovative solutions into off-gassing monitoring practices will be essential for promoting sustainable practices and ensuring compliance with regulatory standards within the oil and gas sector. By embracing thermal imaging technologies as a crucial tool in the industry’s safety arsenal, oil and gas companies can move towards a future where operational excellence and environmental stewardship go hand in hand.