Infrared Thermal Technology in Food Processing: Ensuring Quality and Safety

The food processing industry is responsible for providing safe and high-quality food products to consumers. With increasing consumer awareness and stringent regulations, maintaining quality and safety throughout the production process has become more critical than ever. Infrared thermal technology has emerged as a powerful tool in the food processing industry to ensure the desired quality and safety standards are met.

1. Non-Contact Temperature Measurement:

One of the key advantages of infrared thermal technology is its ability to measure temperature without direct contact. In food processing, this is particularly valuable as it eliminates the risk of contamination. By using infrared cameras or sensors, operators can measure the surface temperature of food products, equipment, or storage areas accurately and quickly.

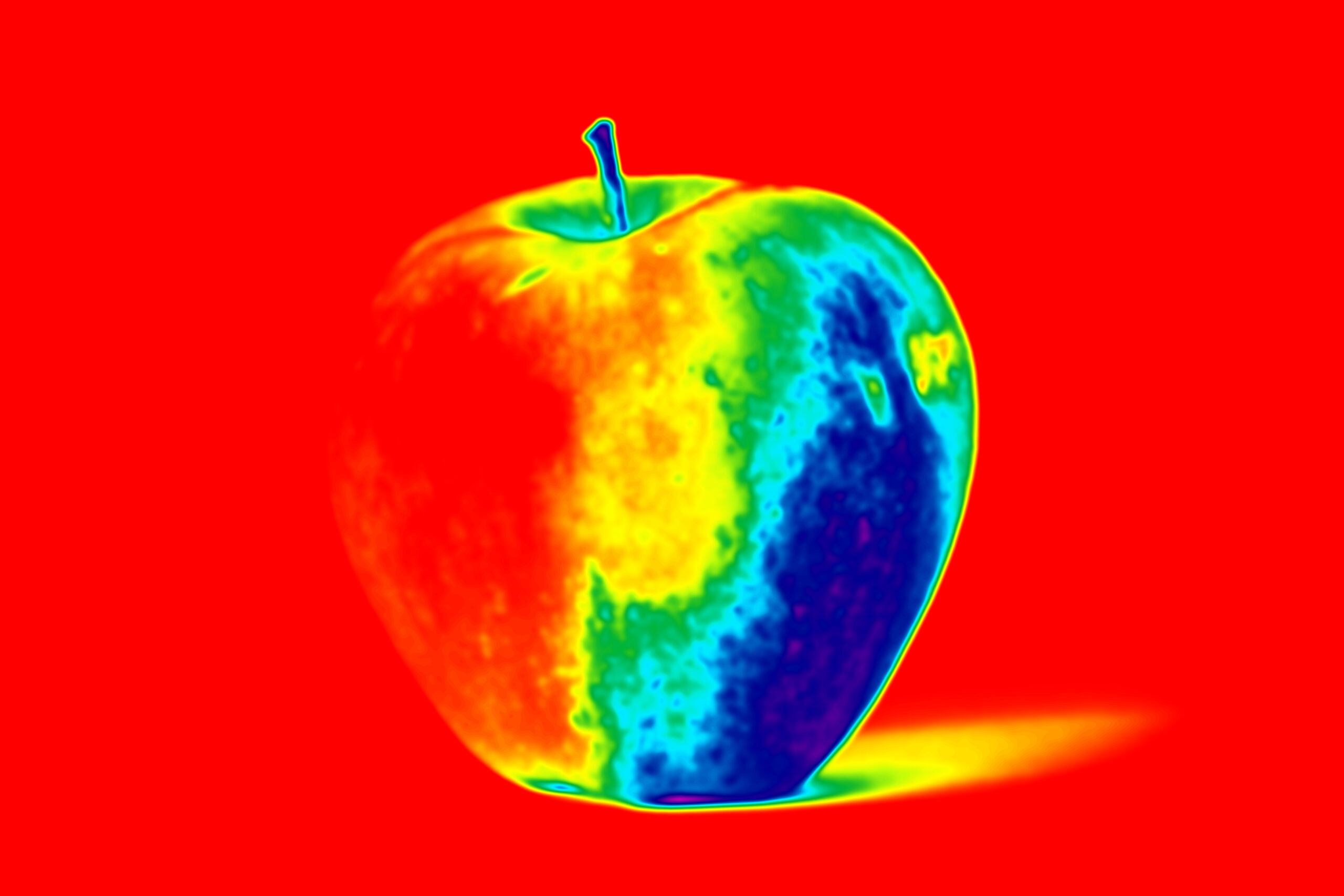

2. Detecting Defects and Contaminants:

Infrared thermal imaging can identify defects or contaminants in food products that may not be visible to the naked eye. Temperature variations or anomalies in the thermal image can indicate potential issues such as spoilage, foreign objects, or improper cooking/heating. Early detection of such problems helps prevent compromised product quality and safety concerns.

3. Monitoring and Controlling Processes:

Infrared thermal technology allows for real-time monitoring of temperature-sensitive processes in food production. Whether it’s baking, frying, pasteurization, or refrigeration, maintaining precise temperature control is crucial. Infrared sensors provide instant feedback on temperature fluctuations, allowing operators to adjust and optimize processes promptly, minimizing the risk of under or overcooking and ensuring food safety.

4. Improving Energy Efficiency:

Efficiency is a key concern in food processing plants, and infrared thermal technology can contribute to energy savings. By using thermal imaging, operators can identify areas of heat loss or excessive heat generation. This information enables them to make necessary adjustments to insulation, equipment placement, or airflow, ultimately reducing energy consumption and operating costs.

5. Enhancing Productivity and Profitability:

By implementing infrared thermal technology, food processing plants can improve their overall productivity and profitability. Real-time temperature monitoring and control help minimize product rejects, rework and recalls due to quality or safety concerns. This not only saves costs but also contributes to maintaining a positive brand reputation and customer satisfaction.

Infrared thermal technology has become an invaluable asset in food processing, ensuring quality and safety standards are met at every stage of production. With its ability to provide non-contact temperature measurement, detect defects and contaminants, monitor and control processes, improve energy efficiency, and enhance productivity, this technology is transforming the industry. As food safety regulations continue to evolve, integrating infrared thermal technology into food processing operations will become a standard practice for the industry’s leading players, safeguarding both consumers and the reputation of food manufacturers.