Implementing Robotics in Your Manufacturing Process, Maximize Uptime with Reliable Equipment Suppliers

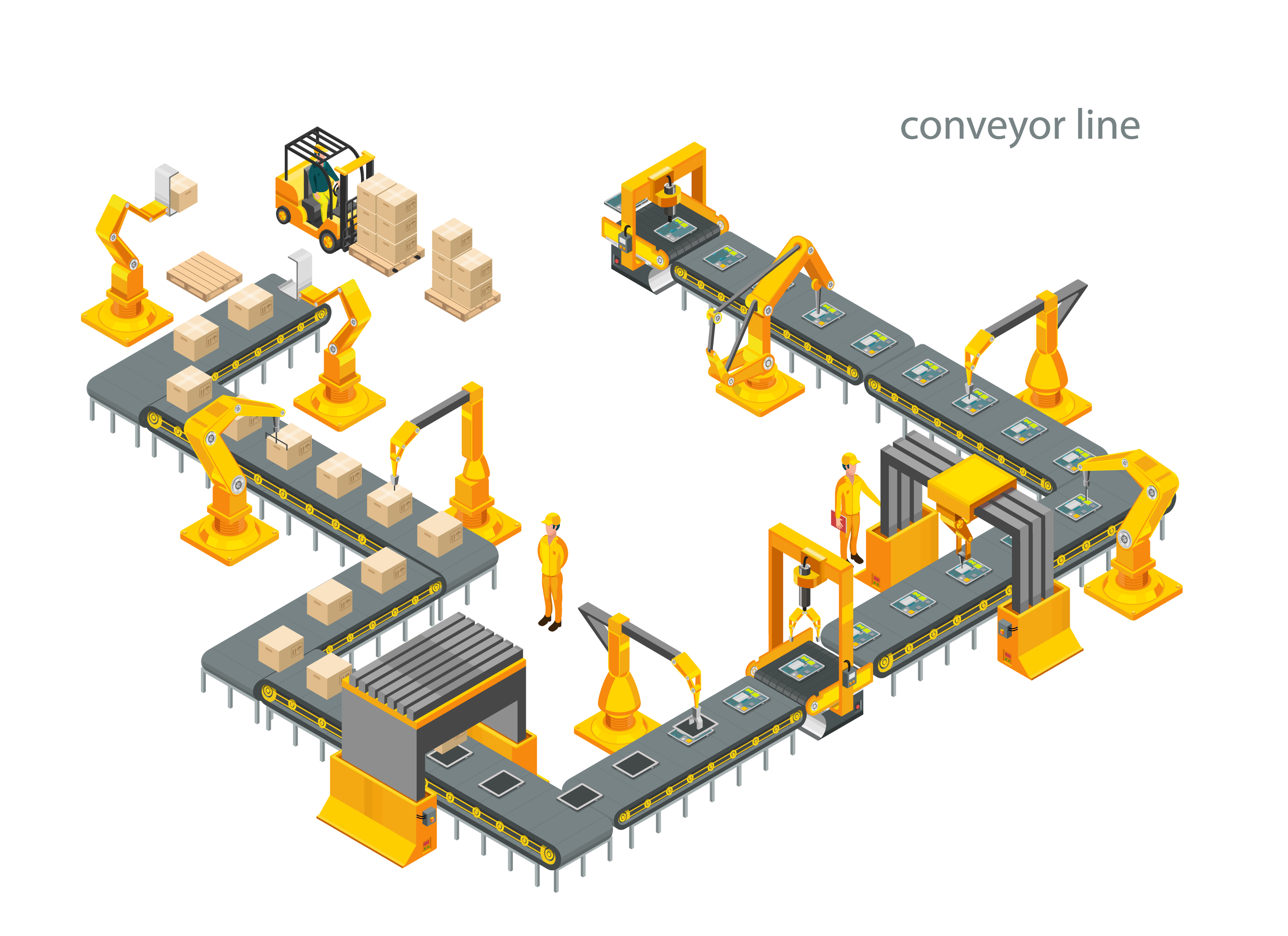

As manufacturing industries continue to embrace automation and robotics to enhance productivity and competitiveness, the importance of having reliable equipment suppliers cannot be overstated. Robotics technology has revolutionized manufacturing processes, streamlining operations, improving accuracy, and increasing production capabilities. However, the successful integration of robotics hinges on the quality and reliability of the equipment sourced from suppliers, reliable maintenance, and the ability to get replacement parts fast. In this blog post, we will explore the significance of having a dependable equipment supplier in supporting your efforts to increase productivity through the implementation of robotics in manufacturing processes.

The Benefits of Implementing Robotics in Manufacturing:

Integrating robotics into manufacturing processes offers a multitude of benefits, including:

1. Increased productivity: Robots can work non-stop, improving throughput and reducing cycle times.

2. Enhanced precision: Robots perform tasks with a high degree of accuracy, minimizing errors and waste.

3. Improved safety: Robots can handle hazardous tasks, keeping human workers out of harm’s way.

4. Flexibility: Robotics systems can be reprogrammed and adapted for different tasks, enabling agile manufacturing processes.

The Role of Reliable Equipment Suppliers:

As the reliance on robotics and automation grows in manufacturing, having a trustworthy equipment supplier becomes paramount for several reasons:

1. Quality Assurance: Reliable suppliers offer high-quality equipment that meets industry standards and regulations, ensuring optimal performance and longevity.

2. Technical Support: A reputable supplier provides comprehensive technical support, including installation, training, and troubleshooting services, to maximize the efficiency of the equipment.

3. Customization Capabilities: Dependable suppliers can tailor process solutions to meet specific manufacturing requirements, offering bespoke solutions that align with the company’s production needs.

4. Continuous Innovation: Collaborating with a forward-thinking equipment supplier grants access to the latest advancements in technology, allowing manufacturers to stay competitive and adopt cutting-edge solutions.

Conclusion:

In conclusion, the increasing adoption of robotics in manufacturing processes underscores the critical role of reliable equipment suppliers in driving productivity and innovation. By forging partnerships with reputable suppliers that offer quality products, technical expertise, customization options, and a commitment to ongoing support, companies can confidently navigate the complexities of automation and achieve operational excellence. As the manufacturing landscape continues to evolve, having a trusted supplier by your side can be the key to unlocking the full potential of robotics technology and staying ahead in a competitive market.