Choosing the Right Pump to Move your materials: A Comprehensive Guide

Pumps are indispensable components in various industrial processes, enabling the movement of fluids and facilitating efficient operations. However, selecting the right pump for your specific application can be a daunting task. With a wide range of options available, it’s essential to consider several factors to maximize performance, energy efficiency, and overall cost-effectiveness. In this comprehensive guide, we’ll explore ten crucial considerations to help you choose the perfect pump for your industrial process.

1. Identify your Application Needs:

Understanding the specific requirements of your industrial process is the first step in selecting the right pump. Consider factors such as the type of fluid being handled, flow rate, pressure, temperature, and any special considerations like abrasiveness or corrosiveness.

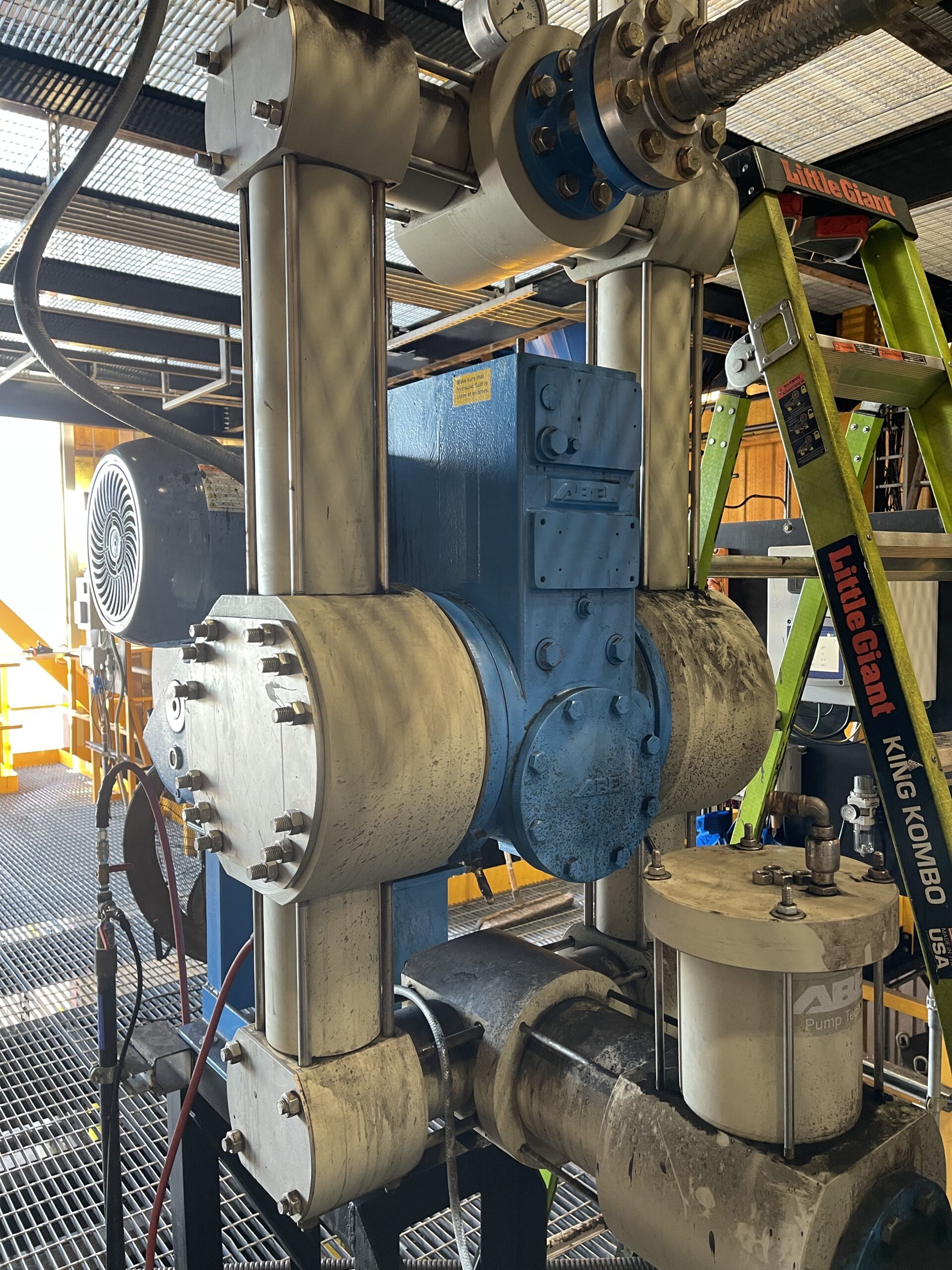

2. Determine the Pump Type:

There are various types of pumps available, including centrifugal, positive displacement, submersible, and axial flow pumps. Each type has its own strengths and limitations. Evaluate your application needs and consult with experts to determine the most suitable pump type for your process.

3. Consider the Material Compatibility:

Ensure that the selected pump materials are compatible with the fluid being handled. Chemical resistance is crucial to prevent corrosion or damage to the pump, ensuring longevity and efficient performance.

4. Evaluate Pump Efficiency:

Efficiency plays a significant role in minimizing energy consumption and operational costs. Look for pumps with high efficiency ratings, such as those meeting industry standards like Energy Efficient Design Index (EEDI) or Minimum Efficiency Index (MEI).

5. Assess Maintenance Requirements:

Consider the maintenance and servicing requirements of the pump. Some pumps may require regular maintenance, while others may have longer intervals between servicing. Factor in the availability of spare parts and access to reliable maintenance support.

6. Examine Total Lifecycle Cost:

Look beyond the initial purchase price and consider the long-term costs associated with pump operation, maintenance, repair, and energy consumption. Choosing an energy-efficient pump with lower lifecycle costs can significantly impact your operational budget.

7. Evaluate Noise and Vibration Levels:

Pumps that generate excessive noise or vibration may lead to discomfort or even damage to nearby equipment. Ensure that the selected pump operates within acceptable noise and vibration levels specified for your application.

8. Consider Environmental Impact:

Environmental considerations are increasingly important today. Look for pumps that adhere to environmental regulations, such as those that are energy-efficient or designed with eco-friendly materials.

9. Seek Expert Advice:

Choosing the right pump can be complex, especially for specialized applications. Consult with expert pump suppliers or engineers who can provide valuable insights and recommendations based on their industry experience.

10. Test and Evaluate:

Before making a final decision, consider testing the pump under real operating conditions or conducting pilot studies. This practical approach allows you to assess performance, reliability, and suitability for your specific industrial process.

Selecting the right pump for your industrial process is a critical decision that can significantly impact your operations and overall productivity. Consider the various factors mentioned above and consult with experts to ensure your choice aligns with your application requirements. With careful consideration and research, you can choose a pump that optimizes performance, minimizes costs, and ensures a seamless industrial process.