Understanding the Importance of Fluid Dynamics in Mixing Processes

- Homesssss

- Understanding the Importance of Fluid Dynamics in Mixing Processes

Understanding the Importance of Fluid Dynamics in Mixing Processes

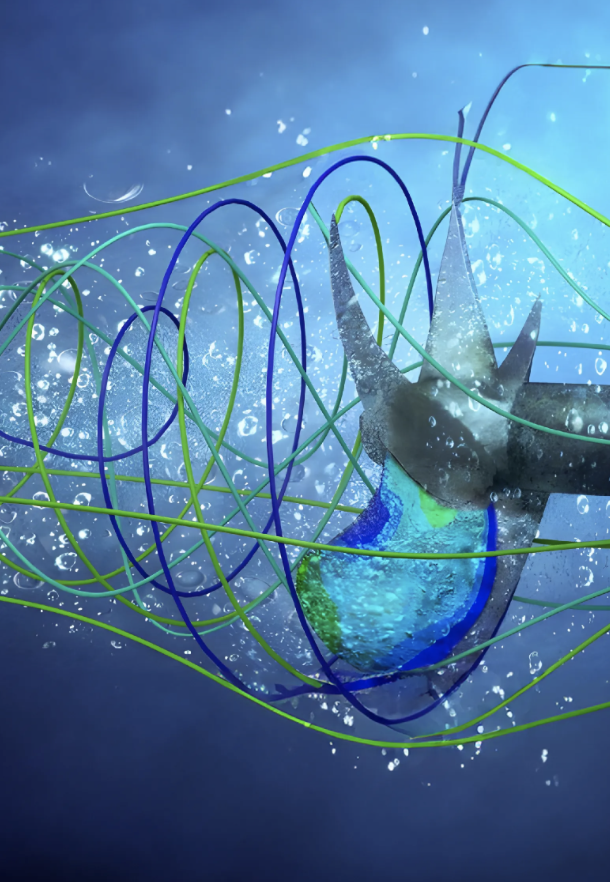

Fluid dynamics is a fundamental aspect of many industrial processes, particularly in mixing applications. Whether you’re working with chemicals, food products, or pharmaceuticals, understanding the principles of fluid dynamics can significantly enhance the efficiency and effectiveness of your mixing operations. In this blog, we’ll explore the key concepts of fluid dynamics and their implications for mixing processes.

What is Fluid Dynamics?

Fluid dynamics is the study of fluids (liquids and gases) in motion. It encompasses the behavior of fluids under various conditions, including flow rates, viscosity, pressure, and temperature. In industrial mixing, fluid dynamics helps us understand how different materials interact when they are combined, which is crucial for achieving uniformity and desired product characteristics.

Key Concepts in Fluid Dynamics

1. Viscosity: This is a measure of a fluid’s resistance to flow. High-viscosity fluids (like honey) flow slower than low-viscosity fluids (like water). When mixing, the viscosity of the components can affect the mixing time and the energy required for effective blending.

2. Flow Patterns: Fluids can exhibit different flow patterns, such as laminar and turbulent flow. Laminar flow is smooth and orderly, whereas turbulent flow is chaotic and mixed. In mixing applications, achieving turbulent flow is often desired because it promotes better mixing and faster homogenization.

3. Shear Force: This refers to the force that causes layers of fluid to slide past one another. In mixing, applying shear force can help break down particles and promote uniform distribution of materials. Understanding how to manipulate shear forces is crucial for optimizing mixing processes.

4. Reynolds Number: This dimensionless number helps predict flow patterns in different fluid regimes. A low Reynolds number indicates laminar flow, while a high Reynolds number indicates turbulent flow. Monitoring the Reynolds number during mixing can help operators adjust conditions to achieve the desired flow regime.

The Role of Fluid Dynamics in Mixing

Understanding fluid dynamics allows engineers and operators to:

– Optimize Mixing Efficiency: By selecting the right mixing equipment and conditions based on fluid properties, you can achieve better mixing results in less time.

– Reduce Energy Consumption: Efficient mixing can minimize energy use by ensuring that the mixing process is effective without requiring excessive power.

– Enhance Product Quality: Properly mixed materials lead to consistent product quality, which is crucial for maintaining standards in industries like pharmaceuticals and food production.

– Scale Up Processes: When transitioning from laboratory to industrial-scale mixing, understanding fluid dynamics helps in scaling up processes without losing efficiency or product quality.

Conclusion

Fluid dynamics is a critical factor in the success of mixing processes across various industries. By understanding the principles of fluid behavior, viscosity, flow patterns, and shear forces, you can optimize your mixing operations, improve product quality, and reduce energy consumption. Whether you’re designing new equipment or fine-tuning existing processes, a solid grasp of fluid dynamics will empower you to make informed decisions and achieve superior mixing results.

Stay tuned for our next blog, where we will explore the future of automation in industrial equipment!